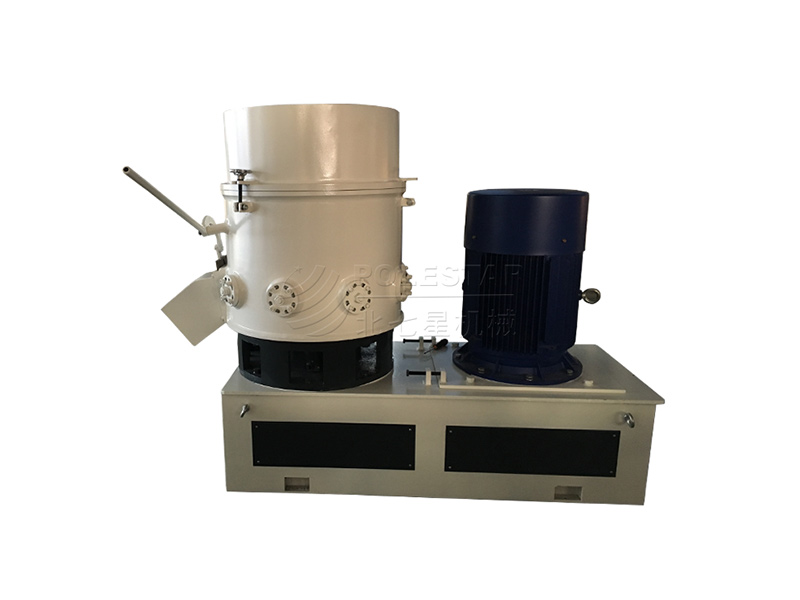

Mashiinka Agglomerator caaga ah ee dib u warshadaynta caaga ah

Faahfaahinta Alaabta

Mashiinka agglomerator caagga ah / mashiinka cufan caag ah waxaa loo isticmaalaa in lagu miiray filimaanta caagga ah ee kulaylka ah, fiilooyinka PET, kuwaas oo dhumucdiisu ay ka yar tahay 2mm si toos ah granuls yar yar & pellets. PVC jilicsan, LDPE, HDPE, PS, PP, xumbada PS, fiilooyinka PET iyo heerkulbeegyada kale ayaa ku habboon.

Sharaxaada

Marka bacda qashinka la soo geliyo qolka, waxa la googooyaa jajabyo yaryar sababtoo ah shaqada burburinta mindida wareegta iyo mindida go'an. Inta lagu guda jiro habaynta burburinta, shayga qooyay kulaylka badan ee dhaqdhaqaaqa is jiid jiidka ah ee walaxda la burburinayo iyo gidaarka weelku waxa ay noqonayaan xaalad caag ah. Qaybaha ayaa isku dhejin doona midba midka kale sababtoo ah shaqada balaastikada. Ka hor inta aysan si buuxda isku dhejin, biyaha qabow ee horay loo diyaariyey ayaa lagu buufiyaa walxaha la jajabiyey. Biyaha si degdeg ah ayay u soo baxayaan, heerkulka dusha sare ee alaabta la jajabiyeyna si dhakhso ah hoos ayey u dhacaan. Markaa walxaha la jajabiyey waxay noqonayaan qaybo yaryar ama granules. Way fududahay in lagu garto qaybaha cabbirkoodu kala duwan yahay waxaana lagu midabayn karaa iyadoo la isticmaalayo walaxda midabka oo la geliyo weelka inta lagu jiro habaynta.

Astaamaha

Mashiinka cufnaanta caaga ah / dhaleeceeyaha dhalaaliyaha caaga ah aragtida shaqadu way ka duwan tahay pelletizer extrusion caadi ah, uma baahna kuleyl koronto, waxayna shaqayn kartaa mar kasta iyo meel kasta oo suurtagal ah. Waa caqli ay si wadajir ah u maamulaan PLC& Computer, fudud oo xasiloon hawlaha, waxayna badbaadin kartaa awood koronto iyo shaqaale ka badan pelletizer-ka caadiga ah. 2- Naqshad xoog leh oo labajibaaran ah oo lagu hayo usheeda dhexe, garbaha waxqabadka sare, Biyaha si toos ah u qulqulaya. 3-Waxaa loo isticmaalaa in lagu beddelo PE, filimka PP/bacaha loo beddelo granules agglomeration. Mashiinka agglomerator caag sidoo kale loo yaqaan aagglomerator film dib u warshadaynta qashinka ah ee filimka balaastiga ah iyo dhumucdiisuna waxay ka yar tahay 2 millimitir alaabta qalabka granulation toos ah.

Xogta Farsamada

| Taxanaha GSL inta badan waxaa loo isticmaalaa filimka PE/PP, bac tolan, bac aan tolmo lahayn, iwm. | ||||||

| Qaabka | GSL100 | GSL200 | GSL300 | GSL500 | GSL600 | GSL800 |

| Mugga (L) | 100 | 200 | 300 | 500 | 600 | 800 |

| Mugga waxtarka leh (L) | 75 | 150 | 225 | 375 | 450 | 600 |

| Daabka wareega (Qty) | 2 | 2 | 2 | 4 | 4 | 4 |

| Biraha go'an (Qty) | 6 | 6 | 8 | 8 | 8 | 8 |

| Awoodda (KG/H) | 100 | 150 | 200 | 300 | 400 | 550 |

| Awood (KW) | 37 | 55 | 75 | 90 | 90-110 | 110 |

| Taxanaha GHX ee loo isticmaalo fiber PET si loo soo saaro walxo salool ah | ||||

| Qaabka | GHX100 | GHX300 | GHX400 | GHX500 |

| Mugga (L) | 100 | 300 | 400 | 500 |

| Mugga waxtarka leh (L) | 75 | 225 | 340 | 375 |

| Daabka wareega (Qty) | 2 | 2 | 4 | 4 |

| Biraha go'an (Qty) | 6 | 8 | 8 | 8 |

| Awoodda (KG/H) | 100 | 200 | 350 | 500 |

| Awood (KW) | 37 | 45 | 90 | 110 |

Qaybaha alaabta

Ma rabtaa inaad Sky ku darto Naqshadeyntaada?

Nala soo xidhiidh maanta si aad ula tashato naqshadaynta.