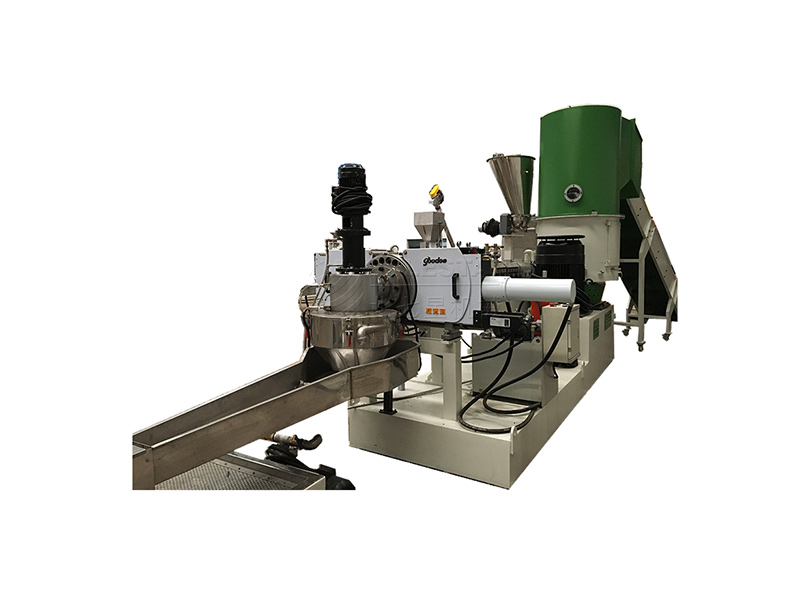

Jarmal Technology Caaga PE PP Granulating Machine

Faahfaahin

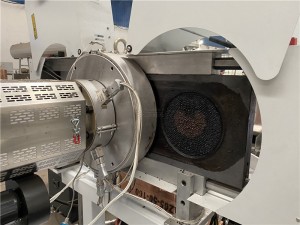

POLESTAR Mashiinka Pelletizer-ka caaga ah/Granulators-ka caaga ah ee bixiya kuleyliyaha isku midka ah ee qaybinta iyo isku-dhafka ayaa ku habboon soo saarista pellets caag ah habka dib-u-warshadaynta. Mashiinka pelletizer balaastikada ah ayaa lagu heli karaa hal (hal mishiin extrusion kaliya) iyo habayn labalaab ah (hal mashiin extrusion weyn iyo hal mishiin sare oo ka sii yar). Waxaa lagu talinayaa in loo isticmaalo diyaarinta marxaladda labalaabka ah ee habka dib-u-warshadaynta sababtoo ah wasakheynta alaabta caagga ah. Waxa kale oo jira ikhtiyaaro kala duwan oo tignoolajiyada pelletizing granule caag ah oo ay heli karaan sida beddelka shaasha ee biyo-xidheenka ah iyo beddelka shaashadda laba-piston si loo hubiyo inaysan jirin wax kala go'a inta lagu jiro isbeddelka shaashadda. Sanduuqa qalabkayaga lagu kalsoonaan karo ayaa kaxeeya si degan si uu u qaso oo u dhaqaajiyo balaastiigga dhalaalay ee foosto. Furka ka samaysan birta sida gaarka ah loo daweeyay waxay hubisaa inay ka hortagto daxalka iyo naaxinta. Nidaamka xakamaynta heerkulka PID oo leh hawo ama habka qaboojinta biyaha ayaa ilaaliya heerkulka shaqada oo joogto ah. "Hot Cut" giraanta biyaha u dhinta wejiga pelletizing iyo "Cold Cut" hababka pelleting strand ayaa diyaar ah iyadoo ku xiran dookhaaga.

Codsiga

Walxaha ceeriin: PE, Filimada PP iyo bacaha

Mashiinka granulator-ka caaga ah / mashiinka pelletizing caag ah / mashiinka pelletizer caag ah oo leh agglomerator waxaa loo isticmaali karaa PE / PP bacaha ama bacaha PP iyo qaar ka mid ah dib-u-warshadaynta pellet parabolic, alaabta waxaa lagu cadaadin doonaa si ka sii adag by agglomeration kaas oo si fudud u tuuri doona si ay u extrude, kaas oo gaari kara awoodda ugu badan ee 100-100kg / saac (waxay kuxirantahay shuruudaha macaamiisha)

Faa'iidada tartanka

1. Heerka otomaatiga sare, isku day sida ugu fiican si aad u yareyso kharashkaaga shaqada oo aad hubiso awoodda wax qabad ee sare.

2. Nidaamka xakamaynta saaxiibtinimo (PLC isku-darka & xakamaynta kala go'a ee mishiin kasta) iyo shaashadda taabashada, fudud ee hawlgalka, kormeerka iyo joojinta degdegga ah.

3. Dhammaan qaybaha la xidhiidha walxo caag ah iyo biyaha waxay ka samaysan yihiin 304 bir ah oo tayo sare leh; Iska ilaali in aanay wasakhda labaad ku dhicin jajabka.

4. Siemens contactor, RKC heerkulka xakamaynta

Tilmaamaha ugu muhiimsan

1. Si toos ah oo toos ah, kantaroolka saaxiibtinimo ee isticmaalaha, aad u hufan, ilaalinta deegaanka iyo badbaadinta tamarta;

2. Siyaabo kala duwan oo wax-soo-saarid ah, sida xadhig qabow, giraanta biyaha, iyo biyaha hoostooda ee agabyada cayriin ee kala duwan iyo shuruudaha wax-soo-saarka;

3. Beddelka shaashadaha ee saldhigyada badan iyo naqshad beddelka shaashadda tooska ah waxay yareyn kartaa shaqada gacanta waxayna hagaajin kartaa ku habboonaanta hawlgalka;

4. Marxalad kali ah iyo laba-jibbaaran, daal badan iyo nidaamka shaandhaynta ayaa hubiya tayada sare iyo alaabta;

5. Ku haboon farsamaynta alaabta kala duwan, sidoo kale waxay si gaar ah u naqshadayn kartaa mashiinka hal shay ama qalab kala duwan, taas oo yareyn karta kharashka maalgashiga macaamiisha.

Xogta Farsamada

Marxaladda kali ah ee agglomeration granulation line

| Qaabka | 70 | 100 | 120 | 150 | 180 |

| Wax soo saarka (kg/saacaddii) | 70-120 | 200-250 | 300-400 | 500-600 | 700-850 |

| Isticmaalka korontada (kWh/kg) | 700-850 | ||||

| Awoodda ugu weyn (kW) | 37 | 90 | 110 | 132 | 185 |

| Awoodda Agglomerator (kW) | 30 | 55 | 75 | 110 | 132 |

| Dhexroorka sare ee maroojin (L/D) | 70 (33:1) | 100 (30-35:1) | 100 (30-35:1) | 100 (30-35:1) | 180 (30-32:1) |

| qiiqa faaruqinta | Ikhtiyaarka | ||||

| Shaashada beddelka | Qaabeynta caadiga ah | ||||

| granulation giraanta biyaha | Ikhtiyaarka | ||||

| granulation xadhig qabow | Ikhtiyaarka | ||||

| granulation biyaha hoostooda | Ikhtiyaarka | ||||

Xariiqda granulation agglomeration double stage

| Qaabka | 70+90 | 100+120 | 120+150 | 150+180 | 180+200 |

| Wax soo saarka (kg/saacaddii) | 110-180 | 200-300 | 300-450 | 500-650 | 700-850 |

| Isticmaalka korontada (kWh/kg) | 0.2-0.35 | ||||

| Awoodda ugu weyn (kW) | 30+22 | 75+37 | 90+45 | 110+55 | 160+75 |

| Awoodda Agglomerator (kW) | 30 | 55 | 75 | 110 | 132 |

| Marooji dhexroorka dibadda (L/D) | 70 (25+12:1) | 100 (25+12:1) | 120 (25+12:1) | 150 (25+12:1) | 180 (25+12:1) |

| qiiqa faaruqinta | Ikhtiyaarka | ||||

| Shaashada beddelka | 2 qaybood oo qaabeynta caadiga ah | ||||

| granulation giraanta biyaha | Ikhtiyaarka | ||||

| granulation xadhig qabow | Ikhtiyaarka | ||||

| granulation biyaha hoostooda | Ikhtiyaarka | ||||

Qaybaha alaabta

Ma rabtaa inaad Sky ku darto Naqshadeyntaada?

Nala soo xidhiidh maanta si aad ula tashato naqshadaynta.